PRODUCT CLASSIFICATION

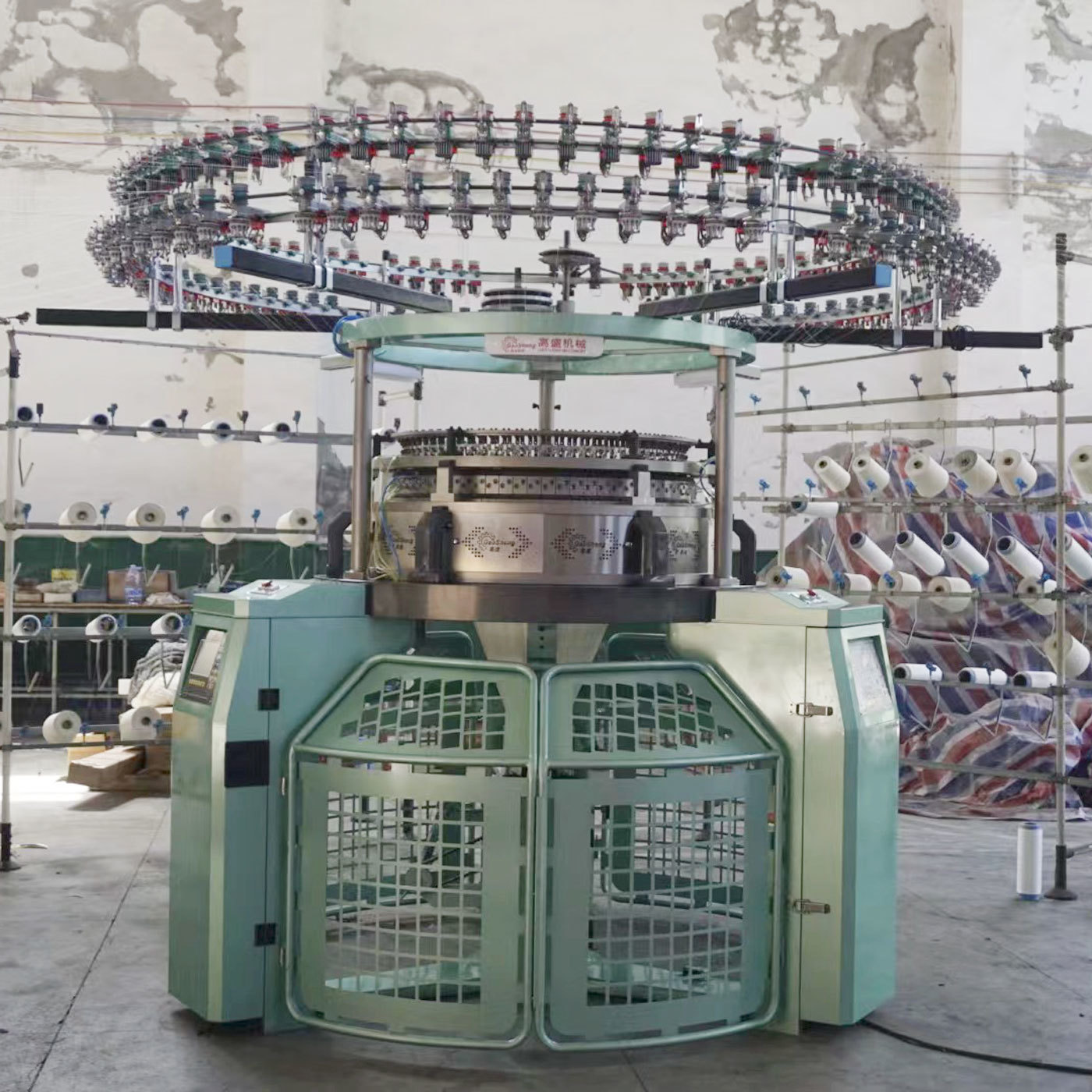

Single jersey computer jacquard cricular knitting machine

The machine use the computer needle selector to select the needle on the needle cylinder, can knitting the jacquard fabric with unlimited pattern range. The computer needle selector can be made into loop, miss and float three power position selector. The process pattern of any complex organization can be changed into a special control command through a computerized pattern preparation system. These instructions control a computerized needle selector on a machine to weave single jersery jacquard fabric.

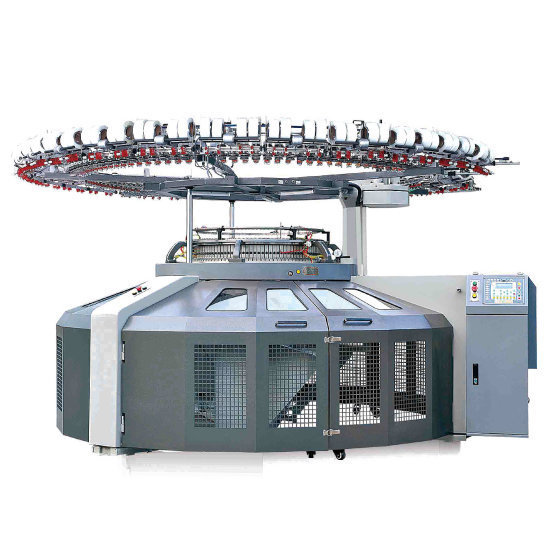

Double jersey knitting machine

When knitting cotton cloth, the cloth surface is smooth, the bar is clear. This machine also can weave gingham, jacquard cloth, straight strip cloth and high quality, high requirements Roman cloth. In particular, the advantages of the air layer fabric with double-sided cotton and spandex intermediate monofilament are particularly significant. (Cam system top two and down four, can be customized top four and down six).

Throught to change Cam, the machine can produce variety kinds fabires. This kind single jersey machine also can throught to changine the knitting parts to make 3-thread-fleece and terry fabric

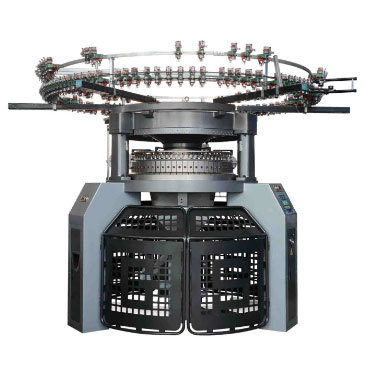

Single body jersey knitting machine

Single body jersey machine could be used for the production of mercerized cotton, polyester cover cotton, single and double mesh , elastic fabric etc., the cloth surface is fine and smooth, clear, not easy to reverse silk

Special cyliner jersey knitting machine

The needle selector could use top and down double cylinders to make loop, miss and floa by two or three positions, could knitting any kinds of fabric. Such as embossed knitted fabrics, striped fabrics, patterned fabrics, transfer printed fabrics, color jacquard fabrics, elastic fabrics, as well as sweaters and fashion products.

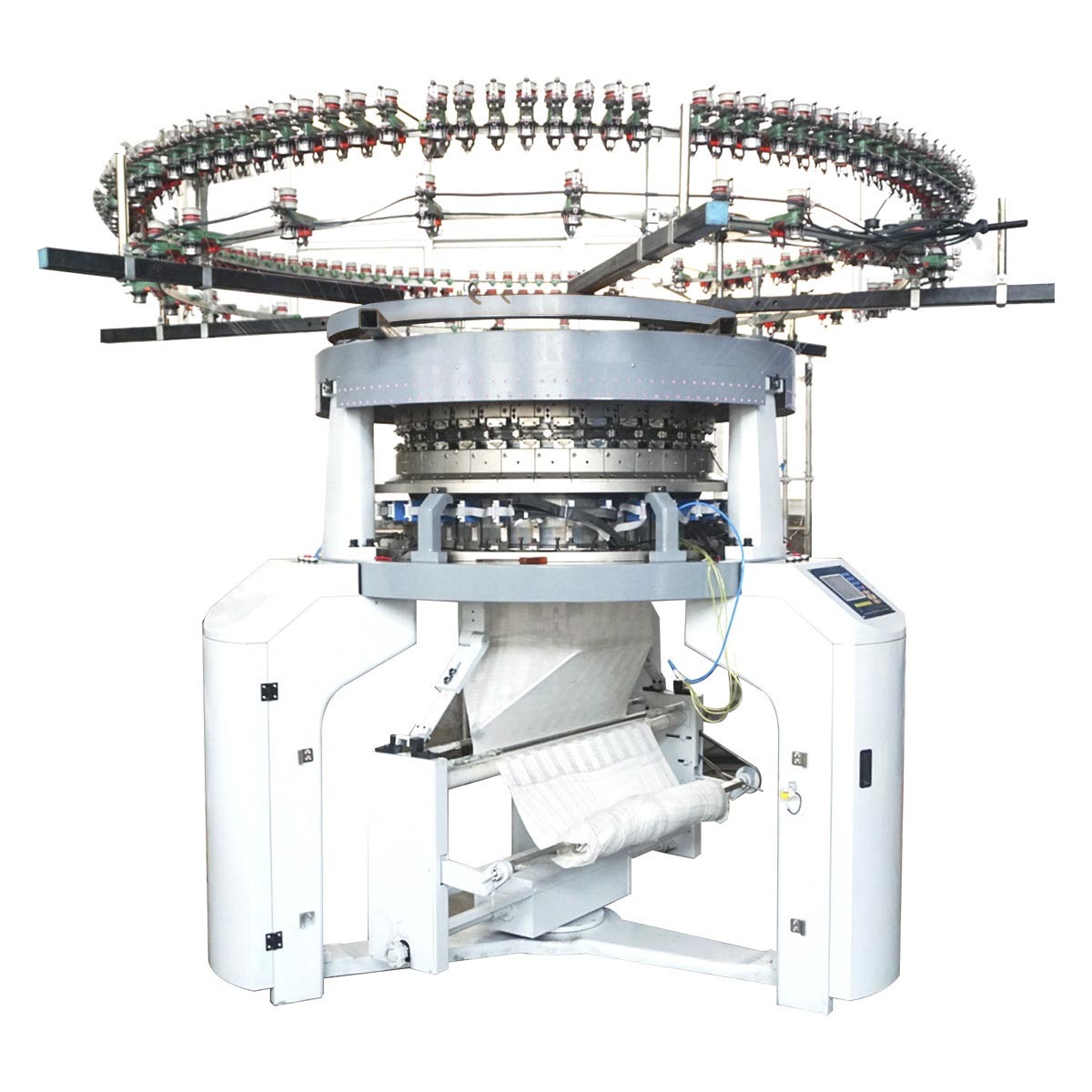

Single Open-width Jersey knitting machine

The single-sided opener has the characteristics that the woven fabric has no crease in the middle, the fabric does not deform, and the machine table has precise and soft cutting and reliable operation performance. So as to reduce waste, save costs and create more profits. Suitable weaving materials are: cotton, artificial yarn, blended yarn, silk thread and artificial wool.

PRODUCT APPLICATION

Goldman Sachs has always focused on technology updates to meet market needs. Can be customized according to the different needs of customers.

Home textiles are also known as decorative textiles. It is a practical textile that beautifies and decorates the living environment. Mainly used in homes and public places. Such as: hotels, restaurant, theaters, dance halls, planes, trains, cars, ships, shopping malls, companies, institutions and many other occasions, for beautification, improve the environment, improve people's life, work comfort has played a great role.

Details

As one of the three elements of clothing, fabric can not only interpret the style and characteristics of clothing, but also directly influence the color and shape of clothing. It presents its own noble perfection and feels soft. In the world of clothing, the fabric of clothing is varied and changing with each passing day. But on the whole, high-quality, high-end fabrics, mostly have the characteristics of comfortable wearing, sweat-absorbent and breathable, hanging, visual nobility, and soft touch.

Details

Good stretchable fabrics continue to promote the convenience of outdoor activities, fast, effective protection of muscle stretching in the power consumption, fabric elasticity makes clothing and movement rhythm to keep pace, on the basis of protecting the surface of the body, greater play to the human ability to break the limit.

Details

Pajamas have different grades and different requirements for fabrics. General pajamas are usually knitted cotton, which are comfortable to wear, sweat-absorbent and soft. High-grade point is silk fabric, very smooth, delicate, wearing a strong sense of comfort.

Details

ABOUT GAOSHENG

Quanzhou Huian Gaosheng Textile Machinery co., Ltd had been specification designing and manufacturing various of hi-tech circular knitting machines, We had long-term experience. Company passed GB/T 19001-2016/ISO 9001-2015 quality management system and CE declaration confirmation.We have devoted continuously to put the innovations in to practice to satisfy the needs of customers. In recent years,our company's production are very popular in our local market.

Gaosheng Company always pay more attention of advanced technology to meeting the market requirements.Can make the knitting machines specially according to customers difference' requirement. Our development tenet is continue bring in lots of advanced human sources,inputting more high-tech production equipments, providing strongly support for company to meet the market need.

INFORMATION

News

01

/

23

News dynamics

Wishing new and old customers a happy New Year and all the best

08

/

31

News dynamics

Our company participates in the ITAM exhibition, welcome guidance 2023 Hall number :Booth Number: H4 - D26

05

/

17

News dynamics

Introduction of single-side knitting machine and double-side knitting machine

Single-sided knitting machines usually need sinker to assist needle withdrawal and yarn bending into loops, while traditional double-sided knitting machines are difficult to knit normally without sinker devices when they are used to knit single-sided products. At present, two methods are generally adopted to solve this problem. One is that most double-sided circular machines are equipped with anti-channeling triangles, that is, when the lower needle is knitted, the upper needle can be pushed out a little and retracted before the yarn is padded. In this way, the protruding upper needle can be used as a holding sinker to press on the old loop of the lower needle that rises and retreats to prevent the old loop from rising together with the needle; another more effective method is a double-sided circular machine with sinker. It also has a sinker device installed on the double-sided circular machine to assist the knitting needles in forming loops. In this way, on the one hand, when weaving double-sided fabrics, there is no need to hang cloth, which can start automatically, and it is easy to resume weaving when cloth falls off or large holes occur. On the other hand, when weaving single-sided fabrics, the sinker on the machine can be used to assist the knitting needles to retreat and bend the yarn to form loops, thus achieving the purpose of exchanging single-sided machines.